- Dwarka, Delhi

- View Mobile Number

Leak Detection & Noise Monitoring

Leading Wholesaler, Importer, Exporters of Air and Gas Leak Tester , Air Leak Testing Machine With Camera, Battery Life Ultrasonic Air Leak Detector, Camera Ultrasonic Air Leak Detector, Digital Ultrasonic Air & Gas Leak Detector, Environmental and Work Place Sound Level Meter, Laser Doppler Vibrometer, Leak Detector with Acoustic Camera, Ultrasonic Air Leak Detector Vpe Series and VPE-2000 Digital Ultrasonic Air and Gas Leak Detector from Delhi.

| Business Type | Exporter, Supplier, Importer |

| Air-leak-tester-leak-detector | |

| Certification | ISO 9001:2008 |

| Type | Leak Detector |

| Material | Plastic |

| Application | Detecting Leaks In Pressurized Pipe Systems |

| Voltage | 47 Volt |

| Special Features | Robustness, Low Weight, Improved Detection With Acoustic Trumpet, Li-Ion Battery, Adjustable Sensitivity |

| Typical Applications | Compressed Air, Gas, And Vacuum Systems; Door Seals |

| Operating Time | Minimum 10 Hours |

| Product Code | LD 450 |

\If gases escape through leaks in pressurized pipe systems (e.g. non-tight screwed connections, corrosion and so on), ultrasonic noises are generated. By means of LD 450, even the smallest leakages which cannot be heard by the human ear and which are not visible due to their size can be detected even from distances of several meters. LD 450 transforms the inaudible signals into a frequency which can be identified by human beings. By means of the comfortable soundproof headset, these noises can be detected even in extremely noisy environments.

The LD 450 leak detector is the advancement of the proven LD 300 and LD 400 and it impresses with its significantly refined sensor technology and its improved support in the tracing of leaks. By means of the integrated laser pointer, which serves for target heading, the leak can be localized more accurately. Through the use of a specially designed acoustic trumpet, a better bundling of the sound waves is achieved. This trumpet acts like a directional microphone, which bundles ultrasonic waves and thus improves the acoustic behavior. Due to the special design of the acoustic trumpet, the use of the laser pointer is not hindered.

The LD 450 meets the requirements of Class I instruments for the norm "Standard Test Method for Leaks with Ultrasound" (ASTM Int. - E1002-05).

Typical Applications:

Leak detection on:

- Compressed air, gas and vacuum systems

- Door seals

Special Features

- Robustness and low weight ensure fatigue-free use in industrial environments

- Improved detection of leakages with the acoustic trumpet

- Modern Li-Ion battery with high capacity, external charger

- Minimum operating time 10 h

- Easy operation via membrane keypad

- Adjustable sensitivity

| Business Type | Exporter, Supplier, Importer |

| Digital Plastic Air Leak Testing Machine With Camera | |

| Application | Plastic Components, Bottles, Containers, Automotive Parts, Medical Devices |

| Leak Test Method | Air Pressure Decay |

| Camera | Integrated High-resolution Camera |

| Display | Digital Touchscreen Control Panel |

| Pressure Range | Adjustable (0 - 1 MPa) |

| Resolution | Up To 0.1 Pa For Precise Leak Detection |

| Data Storage | Built-in Memory With USB / PC Connectivity |

| Power Supply | AC 220V, 50Hz |

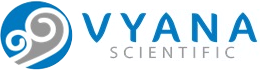

The new leak meters LD 500/510 with integrated camera and leakage calculation are ideal measuring instruments that help to find and document even the smallest leakages (0.1 l/min corresponds to approx. €1 p.a.) easily, even at far distances. The LD 510 is the world’s first leak meter with an additional freely assignable sensor input for all CS sensors. In addition to leakage measurement and detection, all necessary measurements with regard to dew point, flow, pressure, and temperature can also be carried out.

Special features of leak detector LD 500/LD 510:

- Determine leak size (l/min) and potential savings (€/year)

- Detect the smallest leaks at long distances

- Auto level: automatically adapts sensitivity to the environment and reliably eliminates ambient noise

- Capture photographs of leaking parts

- Add descriptions of leaks and necessary actions

- Transmit leak details via USB to desktop software or via Bluetooth to the app

- Generate an ISO 50001 report

- Continuous leak detection for up to 9 hours

- Additional sensor input for CS Instruments sensors (LD 510 only)

Optional accessories for easy localization of leaks:

Detecting compressed air and gas leaks can be challenging depending on the accessibility of the systems. To address this, special accessories are available for the LD 500/510 leak detectors to facilitate leak detection in hard-to-access areas.

These include a special acoustic trumpet, a focus tube with focus tip, a flexible gooseneck, and a parabolic mirror. For more information, please see the additional product images on the left.

| Business Type | Exporter, Supplier, Importer |

| Battery Life Ultrasonic Air Leak Detector | |

| Application | Detecting Ultrasounds For Various Purposes Such As Leaks,Rolling,Arcs,Etc. |

| Frequency | 115 KHz |

| Certification | ISI Certified |

| Driven Type | Battery, Electric |

| Color | Ivory, Light Grey, Light Yellow, Orange, Yellow |

| Detector Type | battery life |

| Size | 0.3m x 0.2m x 0.03m |

| Weight | 0.45Kg |

| storage | 60 minutes of storage |

The mobile Ultrasound Viewer benefits from exclusive technologies from ACB Engineering, specialists in sound cameras for over 20 years. Using the latest video techniques, the MUV is fully automatic—you just have to turn it on and watch where the ultrasound spot is superimposed on the video. The localization accuracy is on the order of one centimeter when the measurement is close and a few centimeters when the measurement is farther away, regardless of the origin of the ultrasounds (leaks, rolling, arcs, etc.). It is possible to record pictures or videos to communicate easily with others.

| Business Type | Exporter, Supplier, Importer |

| SPECIFICATIONS | |

| Certification | ISI Certified |

| Type | Ultrasound Camera |

| Measurement Type | Compressed Air Leak Detection (ultrasonic) |

| Display | Real-time Visual Leak Location On Screen |

| Audio | Headphone Output To Hear Leaks |

| Lighting | 5 LEDs + Ambient Light Sensor For Dark Environments |

| Battery Life | Up To 7 Hours Continuous Operation |

| Weight | 600 G |

| Connectivity | Compatible With Existing LD 500/LD 510 Systems |

| Usability | Intuitive Interface, Minimal Training Required |

| Product Code | LD500/510 |

Ultrasound Camera UltraCam LD 500/510

Shows exactly where compressed air leaks are on the screen and makes finding compressed air leaks much easier – even in harsh environments!

Special features of the UltraCam LD 500/510

- Shows you where the leak is on the screen

- Find leaks during production without interruption of plant operation

- Very intuitive and requires no training

- Lets you hear where the compressed air leak is also through the headphones

- 5 LEDs and ambient light sensor for intelligent lighting in dark environments

- Leak estimation function (l/min or cfm) and cost per year

- Running time of 7 hours for the LD 500/LD 510

- Lightest acoustic camera on the market at 600

- Can be connected to existing LD 500/LD 510

| Business Type | Exporter, Supplier, Importer |

| Digital Ultrasonic Air & Gas Leak Detector | |

| Certification | ISI Certified |

| Weight | 150 Gram |

| Testing Pressure Range | 8 bar |

| Machine Type | Air Leak Testing Machine |

| Application | Detects Leaks And Friction In Industrial Systems |

| Display Type | Digital |

| Automation Grade | Semi-Automatic |

| Power | 42 Volt |

When powerful performance is needed and budgets are limited, choose the versatile Superior AccuTrak® VPE-1000 Ultrasonic Leak Detector. It is the first low-cost digital ultrasonic leak detector, offering extraordinary features at a fraction of the cost of other ultrasonic instruments. The versatile AccuTrak® VPE-1000 features separate ultra-sensitive sensors for both airborne and contact ultrasound. Extremely sensitive to the ultrasonic sound of leaks and friction in industrial systems, the VPE-1000 Ultrasonic Leak Detector uses a technique called "heterodyning" to translate ultrasound to a lower frequency which our ears can interpret. AccuTrak® Ultrasonic Leak Detectors are so sensitive they can hear the blink of an eye, yet most background noise will not interfere with leak detection accuracy. Patented technology uses a microcomputer and digital circuitry, making the AccuTrak® VPE-1000 the most accurate and repeatable ultrasonic leak detector available in its class.

| Business Type | Exporter, Supplier, Importer |

| Environmental Sound Level Meter | |

| Power | Rechargeable Li-ion Battery (USB Charging) |

| Connectivity | USB, WiFi, Cloud Software Support |

| Data Storage | Large Internal Memory With WiFi & Secure Cloud Access |

| Dynamic range | 20 DB(A) - 140 DB(A) |

| Class | IEC 61672-1 Class 1 Or Class 2 (selectable Models) |

| Usage | Exposure Assessments, Factory Noise Mapping, Hearing Protection Assessments, Litigation Defense, Noise Control Evaluation |

| Type | Environmental Sound Level Meter |

| Frequency Range | 20 Hz - 20 KHz |

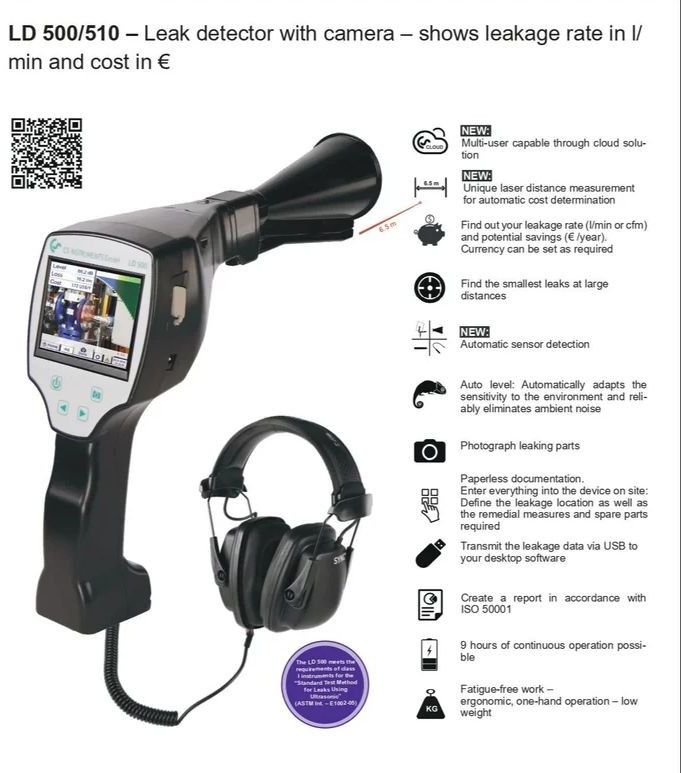

Castle Sound Level Meter

The Castle Sound Meter is the ideal instrument for performing noise measurements in compliance with The Control of Noise at Work Regulations 2005.

Key Benefits:

Hard-wearing, easy-to-use design

Pre-set templates for quick and simple measurements

Available in Class 1 (higher accuracy) or Class 2 versions

Optional Octave Band Analysis for detailed frequency assessments and accurate hearing protection evaluation

Unique Features:

WiFi Data Transfer – instantly send data to your software at the push of a button

Secure Cloud Software – access all your measurement data from any internet browser on any device

Built-in Hearing Protection Database – select suitable hearing protectors directly from the meter when using Octave Band Analysis

Applications:

- Exposure assessments in the workplace

- Factory noise mapping

- HML, SNR, and Octave Band hearing protection assessments

- Litigation defence

- Evaluating noise control effectiveness

| Business Type | Exporter, Supplier, Importer |

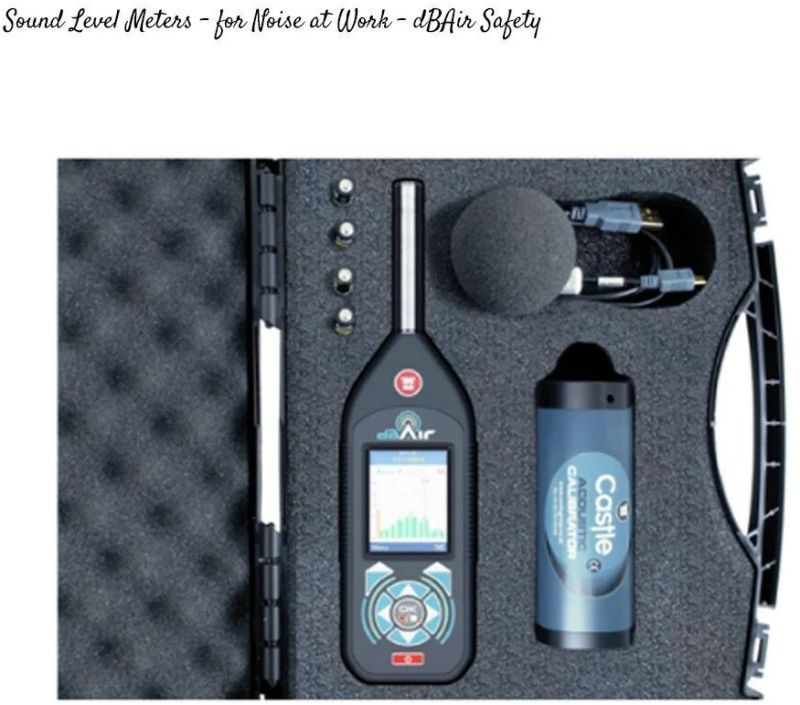

| laser-doppler-vibrometer | |

| Type | Optical Vibrometer |

| Certification | ISI Certified |

| Vibration Frequency Range | 0.01 Hz to 20 kHz2 |

| Working Distance | 1 cm to 5 m |

| Surface Reflectivity | Realistic Surfaces |

| Laser Head Dimensions | 24 x 11.4 x 7.6 cm |

| Temperature Range | 3 - 45 deg C |

| Laser Head Weight | 1.4 Kg |

| Electronic Controller Weight | 3.9 Kg |

| Product Code | LP01 |

The OMS LaserPoint LP01 Vibrometer is based on a patented electro-optical configuration. The system consists of two main components: an optical head and an electronic controller, connected by a cable. The optical head houses a near-infrared laser diode with a built-in high-speed photodetector, an acousto-optic modulator, and a red laser diode for precise beam aiming.The controller includes a demodulator, signal strength indicator, two selectable velocity ranges, and a set of low-pass filter options.

| Business Type | Exporter, Supplier, Importer |

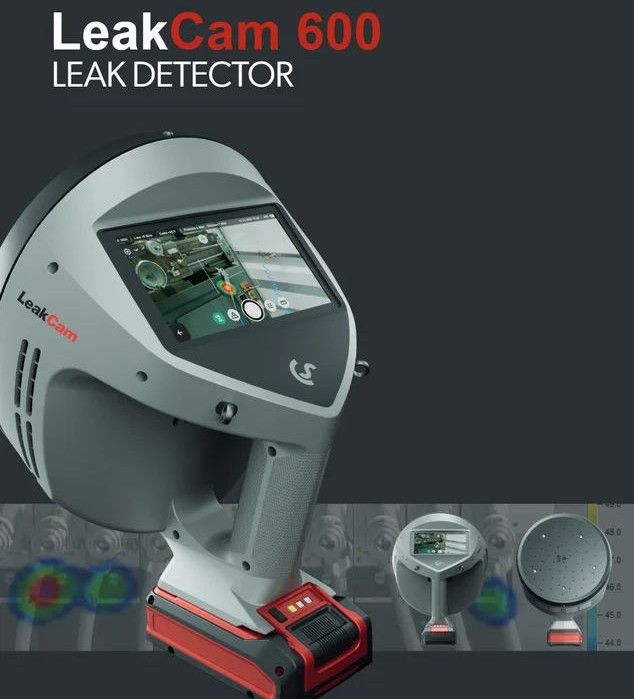

| Air-leak-tester-leakcam-600-leak-detector | |

| Power Source | Replaceable Battery System |

| Type | Leak Detectors |

| Certification | ISI Certified |

| Wave lenght | 630, 660 nm |

| Output power | < 1 mW (laser class 2) |

| Portability | Handheld With Carrying Strap |

| Detection | Compressed Air And Gas Leaks |

| Resolution | 1280 X 720 Pixel |

| Frequency range | 2-80 kHz |

| Product Code | LC 600 |

CS INSTRUMENTS has been a leading global manufacturer of measurement technology for compressed air and gases for more than 20 years. Many years of feedback and experience from several thousand satisfied customers of the previous 300/400/450/500 series leak detectors have been incorporated into the development and research of the LeakCam 600.

Unlike many other manufacturers, CS INSTRUMENTS also has calibration stands and flow meters for precise consumption measurement and leakage measurement of compressed air and gases. This know-how, coupled with over 20 years of experience in the development of leak detectors, has gone into the development of the LeakCam 600.

During development, particular attention was paid to practicality and user-friendliness. What does it really mean for the service technician or maintenance engineer to search for and document gas leaks and compressed air leaks in the production process with a leakage camera in their hand for 8 hours, for example?

Unlike many other leakage cameras, the LC 600 was developed with these points in mind, such as:

The unique integrated laser distance measurement automatically calculates the distance to the leak. There is no need for time-consuming and incorrect distance measurement as with other devices. Precise measurement of the distance to the leak is the most important parameter for accurate leakage calculation.

Special camera module for wide-angle view, allowing the user to quickly gain an overview of larger rooms

- LED for illuminating dark rooms

- Carrying strap, see illustration

- Battery replacement concept

| Business Type | Exporter, Supplier, Importer |

| air-leak-tester-vpe-ultrasonic-leak-detector | |

| Application | Pinpointing Leaks In Air Conditioning,Refrigeration,Automotive,And Other Systems |

| Type | Ultrasonic Leak Detector |

| Color | Blue |

| Frequency | 50-100Hz |

| Certification | ISI Certified |

| Operating Humidity | 95 percent |

| Sensor Type | Ultrasonic |

| Dimensions | 14 x 10 x 3 Inches |

Superior Signal Company is proud to announce the latest version of our most popular ultrasonic leak detector – the 3rd generation AccuTrak® VPE. Featuring all-new internal circuitry, the improved AccuTrak® VPE stands out above all other ultrasonic leak detectors in its class. With even greater sensitivity and a number of new features unique to the VPE, no competitive ultrasonic leak detectors come close.The patented Superior AccuTrak® VPE Ultrasonic Leak Detector is a state-of-the-art, non-invasive ultrasonic leak detector that can detect both pressure and vacuum leaks of any gas. The AccuTrak® VPE is ideal for pinpointing leaks in air conditioning, refrigeration, automotive, and other systems. AccuTrak® Ultrasonic Leak Detectors are extremely sensitive to the ultrasonic sound of a turbulent gas leak. Using a technology called "heterodyning," they translate ultrasound to a lower frequency that your ear can interpret. AccuTrak® Ultrasonic Leak Detectors maintain the original sound characteristics of the ultrasound, making it possible to distinguish leaks from other competing background sounds. AccuTrak® instruments are so sensitive you can actually hear the blink of an eye, yet most background noise will not interfere with detection accuracy.

| Business Type | Exporter, Supplier, Importer |

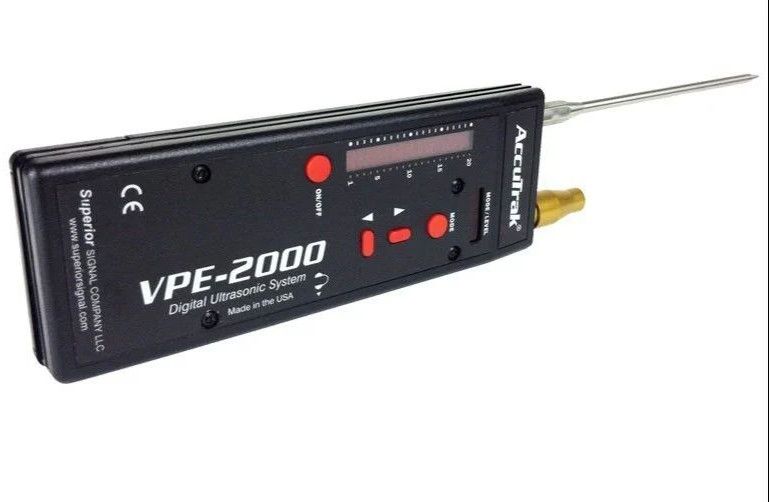

| VPE-2000 Digital Ultrasonic Leak Detector | |

| Application | Leak Detection,Steam Traps,Valves,Bearings,Electrical Inspection,Pneumatics,Hydraulics,Vibration,Fan Belts |

| Country of Origin | India |

| Certification | ISI Certified |

| Detection Method | Airborne & Contact Ultrasonic Sensors |

| Indicators | Digital LED Alphanumeric + Bar-graph Display |

| Functions | Peak Hold, Digital Mode Selection, Volume & Sensitivity Controls |

| Power Supply | Battery Operated |

| Accessories Included | Headset, Contact Probe Extension, Carrying Case, Protective Pouch, Batteries, Manual, Training Video |

| Product Code | AccuTrak VPE-2000 |

The Superior AccuTrak® VPE-2000 Ultrasonic Leak Detector is the first digitally controlled ultrasonic leak detector. Like two instruments in one, it uses two independent sensors supported by separate electronic circuits configured specifically to their own sensor. This assures optimum sound clarity and frequency response. When switching between the airborne and contact sensors, all settings are retained in memory! Digital LED meters let you establish baselines, perform trending, and accurately repeat these tests better than older, more expensive analog instruments.

VPE-2000 Ultrasonic Leak Detector Applications

The VPE-2000 is perfect for schools, hospitals, hotels, factories, and other large institutional or industrial environments. The VPE-2000 Ultrasonic Leak Detector is ideal for a variety of leak detection applications and plant maintenance applications.

Leak Detection: Air Leaks, Vacuum Leaks, Refrigerant Leaks; ANY Compressed Gas!

Steam Traps: Detect live steam loss in seconds!

Valves: Detect/hear internal leakage in check, ball, needle, gate, or any type of valve! Diagnose thermal expansion valves in just five minutes!

Bearings: Hear wear and lubrication problems before damage is done!

Electric Arc and Corona: Inspect circuit breakers, relays, and bus bars! Check for corrosion on contacts and proper insulation!

Pneumatics and Hydraulics: Inspect controls, hoses, tools, fittings, and internal cylinders with ease!

Vibration: Detect the ultrasonic sound generated by excessive friction!

Fan Belts

VPE-2000 Ultrasonic Leak Detector Features

- Digital LED Indicators (Alphanumeric and bar-graph)

- Digital Frequency Selection (With SONIC Probe Mode)

- Digital PEAK HOLD Feature

- Separate Volume and Sensitivity

- Digital Mode Selection

- Stores all Settings in Memory

- Wide Dynamic Range (256 Steps)

Includes Everything You Need

- Instrument

- Headset

- Contact probe extension kit

- Hard carrying case

- Protective canvas pouch with vinyl window

- Batteries

- Manual and video overview